2.1. Non-Destructive Assessment

The pilot structure is an existing reinforced concrete structure of defined geometry which requires restoration. The most suitable retrofitting approach was based on restoration principles and structural and materials requirements. In order to determine the most suitable retrofitting option in terms of material and construction procedures, the old structure had to be thoroughly assessed through non-destructive and materials analysis techniques.

The assessment of the existing structure included the documentation of historical records, the appraisal of defects including the creation of a catalogue of defects and mapping of defects. This was conducted in four stages over a period of 10 years between 2009 and 2019 in order to assess variations in degradation with time. In addition, non-destructive tests were conducted in order to assess the materials, structure and overall performance. Non-destructive tests were carried out as summarized in the table above and as outlined below, in particular to verify details, locate reinforcement and document the state of the materials and the structure.

The NDT was followed by the assessment of materials extracted from different parts of the structure to assess, the concrete density, compressive strength, depth of carbonation, chloride content, concrete petrography; and testing on steel samples extracted from the structure. The assessment was also important to provide input data for a finite element model of the structure was created to enable to structural analysis with respect to different load conditions and to define the stress distribution in the structure.

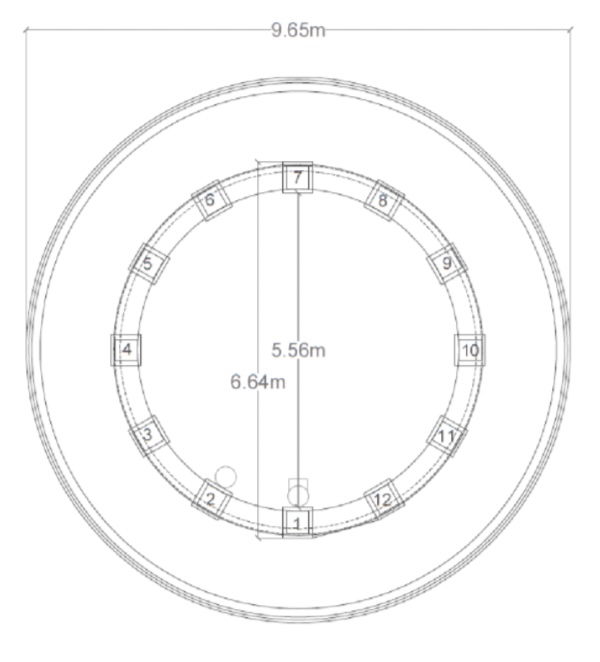

Ground Penetrating Radar

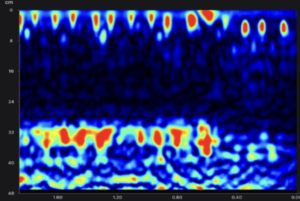

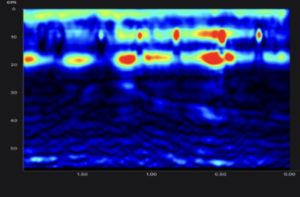

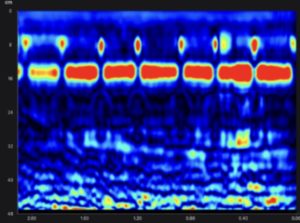

The Ground Penetrating Radar investigation of the water tower was conducted in order to identify the location of reinforcement, inserts and other features. In addition, GPR was also used for the

3D mapping of reinforcement within the structure, understanding of complex detailing and confirmation of section sizes.

Figure 10. GPR of the Existing Structure

Figure 22. Geo-Radar investigation of the various components (columns, shell elements)

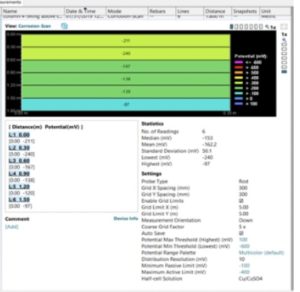

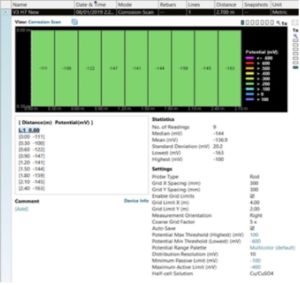

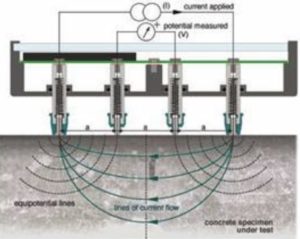

Corrosion Potential of Reinforcement Potential

The Corrosion Potential of reinforcement was determined using the Half Cell technique. The entire structure was scanned in order to identify the state of reinforcement prior to intervention.

Figure 23. Corrosion Potential of reinforcement (Half Cell investigation).

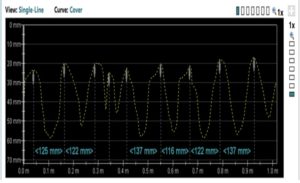

Cover meter survey

The Cover meter survey was conducted in order to conduct an assessment of the location of Reinforcement, type of reinforcement and cover. The entire structure was scanned. In addition the methodology was used also for the verification of structural details and results were compared to other data generated through other techniques as outlined below.

Figure 24. Cover Meter Survey

Ultrasonic Technique

The Ultrasonic technique was applied in order to assess the performance of the concrete and in particular to identify voids or delaminated concrete and concrete sections analysis.

Figure . Ultrasonic Flaw detector

Schmidt Hammer, UPV, Moisture, Resistivity.

Additional analysis was conducted on the existing structure including a Schmidt hammer survey on all surfaces to determine delaminated areas which were mapped and also to indirectly assess compressive strength throughout the structure (These results were compared to the compressive strength test results). Additional tests included UPV (Ultrasonic Pulse velocity, Moisture at the surface and Resistivity of the concrete.

Schmidt Hammer survey conducted throughut the structure / Resistivity of Concrete

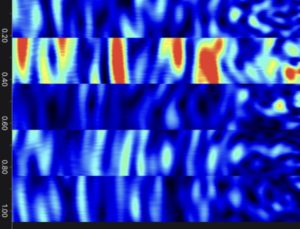

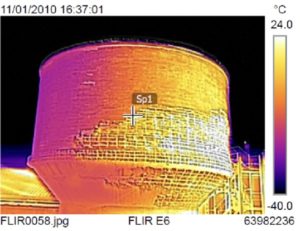

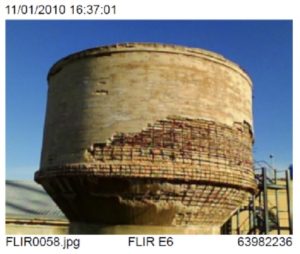

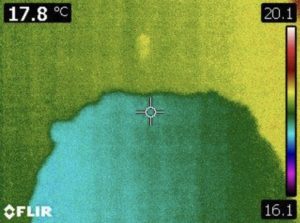

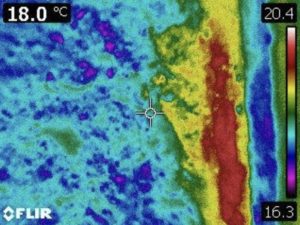

Thermal Imaging – Infra-red Camera

Thermal Imaging was applied to the structure in order to help identify and assess delaminated, spalled concrete. The results consisting of images were compared to the results obtained from other tests in order to calibrate and verify the methodology.

Figure 25. Thermal Imaging – Infra-red Camera Assessment of delaminated, spalled concre

Figure x . Identification of delaminated areas, spalling and other defects on the concrete surface using the thermal images.

2.2 Materials

Advanced materials namely Ultra high durability concrete (UHDC) and textile reinforced concrete (TRC) were developed and analysed through different experimental programmes at the University of Malta. Specific mixes were selected and analysed further through an experimental programme for application in the strengthening of the Reinforced Concrete Water Tower.

The UHDC was development as a self-healing, self-compacting fibre-reinforced mortar. The Ultra High Durability Concrete (UHDC) was applied as a thin jacket, in the strengthening of the columns. The material was produced using different mixes which are based on crystalline admixtures and a nano-additives. The mixes were applied as a jacket to different columns for assessment of performance over time. The TRC was developed based on a carbon fibre textile mesh with resin embedded in mortar and analysed in detail. The material was applied as a thin layer, to the shell elements of the water tank. A monitoring strategy was developed which included an advanced Sensor network system, intended for the long-term monitoring of the structure. The advanced Sensor Network System included a Durability Monitoring system based on Galvanic, Resistivity and Embedded Reference Electrode sensors, Structural Health Monitoring and Environmental Monitoring.

Durability Assessment included the assessment of Assessment of direct and indirect durability parameters on cored specimen. Different samples were extracted and assessed with respect to Elevation, orientation, element type.

Figure . Durability testing of cored specimne (direct and indirect durability parameters)

-

Microtremor assessment of Structure

Ambient vibration measurements

The ambient vibration method is a common tool used to investigate both soil properties, site response analysis as well as evaluate the dynamic properties of building and human-made structures. This technique allows to evaluate the potential peak which corresponds to the fundamental frequency of the investigated site (Bonnefoy-Claudet et al., 2006). The ambient noise wavefield is the result of the combination of unknown portions of both body and surface waves. If the first are prevailing, the ratio is mainly induced by SH resonance in the superficial layers whereas, if Rayleigh surface waves predominate, the theoretical ellipticity dictates the observed curves (Nogoshi and Igarashi, 1971; Fäh et al., 2001; Scherbaum et al., 2003).

The ambient noise was recorded at several locations within and on water tower (Fig. 2) using a Tromino seismometer (www.tromino.eu) which is a compact 3-component velocimeter. Measurements taken at a number of points inside and on the rim of the drum, at points on the sides and at ground level. Time series of ambient noise, having a length of 20 minutes, were recorded with a sampling rate of 128 Hz. Following the guidelines suggested by the SESAME (2004) project the recorded signal was divided in non-overlapping time windows of 20 s. For each window a 5% cosine taper was applied and the Fourier spectra were calculated. The spectra of each window were smoothed using a Konno-Ohmachi window (Konno and Ohmachi, 1998) fixing the parameter b to 40. Finally the resulting HVNR, in the frequency range 0.5-60.0 Hz, was computed estimating the logarithmic average of the spectral ratio obtained for each time window, selecting only the most stationary and excluding transients associated to very close sources. Mean horizontal spectrum is divided by vertical spectrum, to give H/V ratio as function of frequency (mean overall windows). For man-made structures, the peak frequency represents modal resonance frequencies. Figure 3 reports the observed modal behaviour of water tower. Results show a very consistent single frequency of around 2.8 Hz. The structure appears to oscillate very rigidly at the fundamental mode.